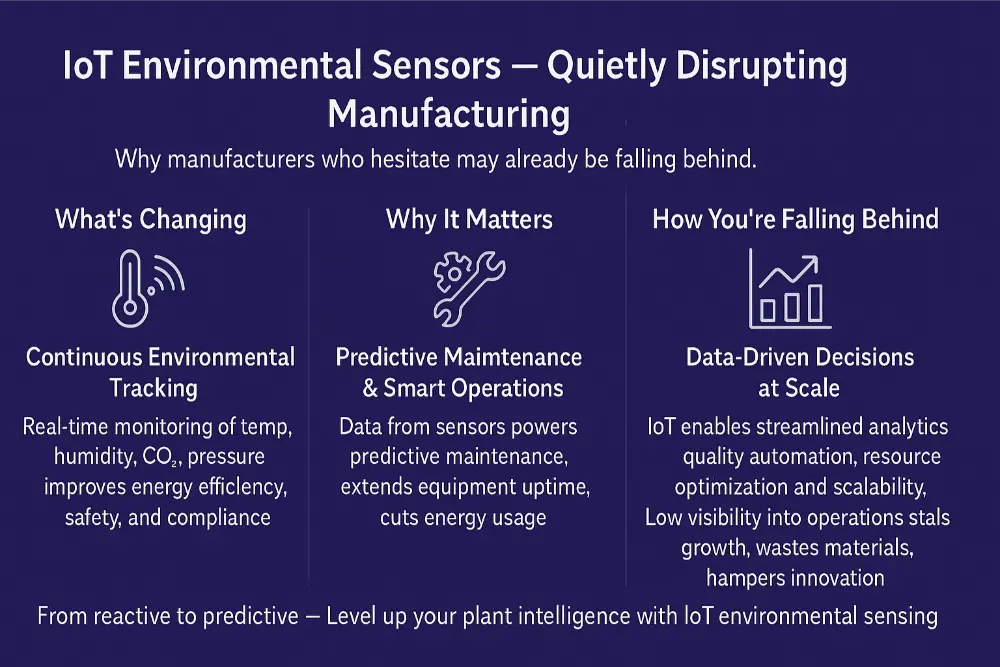

TL:DR: IoT-enabled environmental sensors help factories track these conditions in real time, giving teams the clarity they need to prevent issues before they start. The result? Smoother operations, fewer surprises, and a safer, more efficient workplace.

Key Takeaways:

- Manual checks often miss critical changes in environmental conditions.

- Real-time data from IoT sensors helps catch problems early and reduce downtime.

- Integrating sensors with existing systems boosts productivity without disrupting workflows.

- Smarter alerts and long-term data insights support better planning and decision-making.

On a factory floor, even a small shift in temperature or air quality can cause delays, safety issues, or failed audits. That’s why more manufacturers are turning to IoT-enabled environmental sensors. These smart tools track key conditions like humidity, gas levels, and air pressure in real time. Instead of reacting to problems, teams can respond quickly and stay ahead of costly disruptions. It’s a practical way to keep operations steady, safe, and efficient.

The Problem With “Good Enough” Monitoring

Manual Checks Waste Time and Miss the Real Issues

Many factories still rely on outdated thermostats, manual logs, or occasional spot checks to monitor environmental conditions. But these methods rarely capture sudden changes in temperature, humidity, or air quality when they happen.

That delay in detection can snowball into serious issues like product defects, non-compliance, or even health hazards for workers.

Regulations Are Getting Stricter, and Precision Matters

Industries like pharmaceuticals and semiconductors face tighter regulatory requirements than ever before. Auditors expect accurate, well-documented data that can be accessed quickly.

In this environment, guesswork and patchy monitoring aren’t just risky; they could result in penalties or lost business.

Reliable, up-to-the-minute environmental data has become a basic requirement for manufacturers who want to stay ahead of regulations and avoid costly setbacks. It’s no longer something to consider later, t needs to be built into your process today.

What Makes IoT-Enabled Sensors So Powerful

Real-Time Data That Actually Means Something

Modern IoT environmental sensors provide live, precise readings on essential conditions, including:

- Temperature

- Humidity

- Dust levels

- Toxic or flammable gases

- Air pressure

This kind of insight doesn’t just help with compliance. It plays a real role in maintaining product quality, equipment performance, and workplace safety. Having this data at the right time can help prevent costly mistakes.

Infrared detection, for instance, is one way sensors provide extra precision. You can learn more in our article on Infrared Detection Applications: 5 Key Benefits for Environmental Monitoring.

Easy to Plug Into What You Already Use

One of the biggest advantages of IoT environmental sensors is how smoothly they connect with the systems you already rely on. There’s no need for a massive infrastructure overhaul or complicated integrations.

These sensors can be easily linked to:

- SCADA systems for real-time control and monitoring

- ERP platforms to align data with operations and reporting

- Building Management Systems (BMS) for centralised facility control

- Mobile dashboards that let your team stay informed on the go

This kind of seamless integration means your team can access valuable environmental data without disrupting current workflows. It fits into your operations, rather than sitting off to the side as another standalone tool.

If you’re interested in how IoT and environmental sensors work so well together in manufacturing environments, take a look at our article on Environmental Sensors and the Internet of Things: A Match Made for Effectivity. It offers a deeper look at why this pairing works so well in helping factories operate with more control and less guesswork.

Why the Smart Manufacturers Are Already Onboard

Why Smart Manufacturers Are Already Onboard

- Catch Problems Early: Sudden shifts in humidity or pressure can quietly create serious problems, from product defects to equipment strain. With real-time alerts from IoT sensors, your team can respond quickly and avoid things spiralling out of control.

- Cut Down on Downtime: Excess heat or dust doesn’t just make machines work harder, it can bring them to a halt without warning. With continuous monitoring in place, you can spot trouble before it leads to breakdowns, keeping your lines moving without costly interruptions.

- Keep People Safe and Comfortable: Air quality issues like high CO2 or VOCs can go unnoticed until they affect how people feel or perform. IoT sensors help create a healthier space by alerting you early, so you can fix problems before they become risks to health or morale.

More Than Just Data: Actionable Insights

Historical Trends for Smarter Planning

When you have a solid history of environmental data at your fingertips, you can stop guessing and start making confident decisions. Instead of always reacting to problems after they happen, your team can begin to spot patterns that quietly impact everything from equipment wear to product quality.

This knowledge helps you fine-tune HVAC settings, cut down on energy bills, and even plan maintenance before small issues grow into costly repairs.

It also means less waste and fewer unexpected hiccups. By learning from the conditions that affected performance in the past, you can make smarter choices that keep your operations stable, efficient, and running smoothly day after day.

Alerts That Actually Help

In many factories, alert systems send out so many notifications that staff begin to tune them out. Important warnings can get lost in the noise.

IoT environmental sensors help by letting you customise alerts that are timely and easy to understand.

Here are a few examples:

- A sudden spike in temperature that puts product quality at risk

- Gas levels approaching safety thresholds that could endanger staff or equipment

- A quick shift in air pressure that might signal a leak or blocked airflow

- A gradual increase in humidity that may impact storage or sensitive production areas

These focused alerts help your team respond quickly to what truly matters, without wasting time sifting through unnecessary messages.

How It Works with Minerva’s Environmental Monitoring Solutions

Minerva Intra provides monitoring systems that are easy to scale and flexible enough to suit different industrial setups. Whether you’re running a single production room or managing several facilities, their systems adapt to your needs.

The modular design means you can choose the sensors that make sense for your operations, such as those for gas detection, temperature, or pressure.

The platform is cloud-based, allowing secure access to data anytime, anywhere. It’s built to support key compliance requirements, including ISO and GMP standards.

More than just a supplier, Minerva works alongside clients to plan, install, and maintain monitoring solutions that align with how each facility actually runs.

Visit our Environmental Monitoring Page to explore the solutions in detail and schedule your session.

Ready to Future-Proof Your Manufacturing Facility?

Don’t let outdated monitoring drag your facility down or leave your team in the dark.

Our experts will help you identify gaps, recommend the right IoT-powered sensors, and show you how to make smarter, safer, and more efficient decisions based on real-time data.

Book a free, no-obligation consultation with us today.