TL;DR: Accurate, traceable flow measurement and regular, documented calibration protect revenue, reduce billing disputes and keep you compliant.

Key Takeaways:

- Use high-accuracy meters and ISO-traceable calibration at billing points.

- Fix installation issues: straight runs, flow conditioners and proper grounding.

- Keep a calibration schedule, certificates and an uncertainty statement on file.

- Add a check meter or secondary metering for high-risk flows.

Accurate flow measurement separates fair billing from costly disputes, audits and legal headaches.

When meters drift or are poorly installed, businesses lose revenue, customers lose trust and regulators flag compliance issues.

This article outlines how to choose the right meter, set up a robust calibration programme and document uncertainty so measurements stand up in commercial agreements and audits.

We base recommendations on recognised standards, accredited laboratories and field-proven practice so you get guidance you can defend.

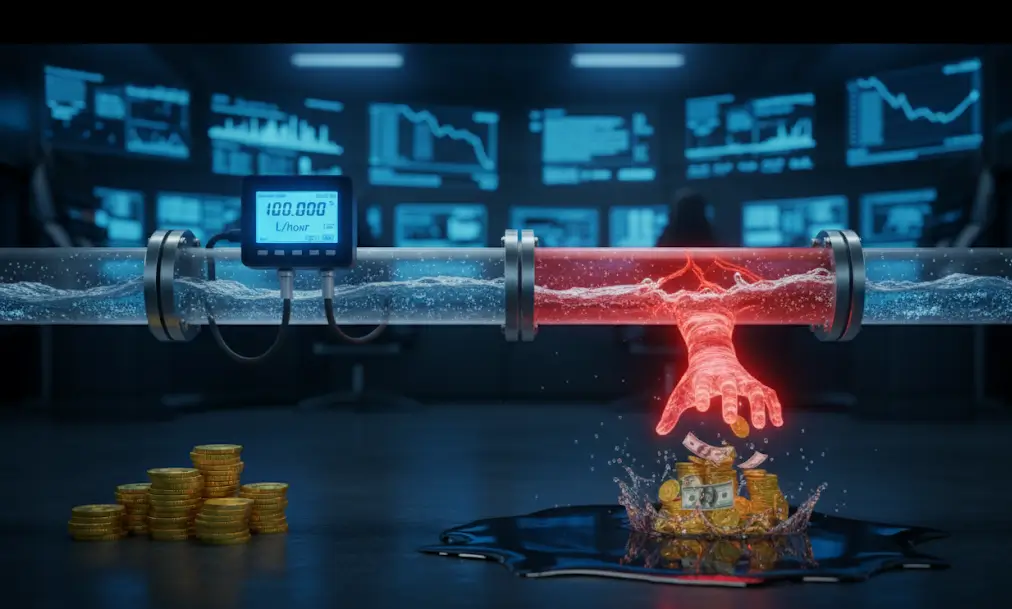

The True Cost of Sloppy Flow Metering

When a meter runs outside its specification you can either lose measurable revenue or trigger customer complaints and disputes.

A small error of 0.5 to 1 percent may seem minor until it is multiplied across millions of litres or multi year contracts, turning a tiny drift into a major financial issue.

What Billing-Grade Accuracy Actually Means

Billing-grade accuracy means a verified reading backed by a quantified uncertainty and a clear statement of what might affect that result.

Calibration should be traceable to national standards and supported by certificates so readings hold up in commercial discussions and regulatory audits.

Choose The Right Meter

Not every meter is appropriate for custody transfer or high-value billing. Coriolis and positive displacement meters are the usual front-runners for highest accuracy.

Why Coriolis Often Wins

Coriolis meters measure mass directly so you do not need separate density or temperature corrections.

They are commonly specified to 0.1 to 0.5 percent accuracy, which fits custody transfer applications where every decimal point matters.

Key benefits:

- Direct mass measurement cuts out extra calculations and reduces cumulative error.

- Strong stability across temperature and pressure changes supports long-term accuracy.

- Good compatibility with ISO 17025 traceable calibration helps satisfy audit and E-E-A-T expectations.

When Positive Displacement Makes Sense

Positive displacement meters give excellent volumetric accuracy on viscous fluids and at low flow rates.

They are mechanically simple and easy to verify, making them a strong choice where counting pulses is preferred.

Key benefits:

- High repeatability for thick or sticky products that challenge other meter types.

- Simple verification methods and visible mechanical operation aid confidence during inspections.

- Low sensitivity to swirl at low Reynolds numbers keeps uncertainty manageable.

When to Avoid Cheaper Options for Billing

Clamp-on ultrasonics and basic mechanical meters can be useful for monitoring but often do not meet tight billing tolerances.

For commercial metering choose technology based on fluid properties, expected flow range and a documented uncertainty budget rather than initial price.

Practical guidance:

- Avoid clamp-on units where pipe condition or poor coupling increases measurement uncertainty.

- Do not rely on basic mechanical meters for custody transfer unless you have a full uncertainty statement and recent calibration evidence.

Installation Matters

A perfect meter can still give poor results if the pipework and flow conditions are wrong.

Follow the manufacturer straight-run guidance, fit flow conditioners where advised and avoid placing fittings or valves too close to the sensor.

Common Installation Pitfalls

Common issues include bends, reducers, nearby valves and corroded pipe bores, all of which disturb the flow profile and add measurement error.

Before commissioning, verify pipe alignment, electrical grounding and that the pipe interior is clean and free of damage.

Environmental and Site Issues to Check

Site factors such as temperature swings, pressure fluctuations and suspended solids will change meter behaviour over time.

Build these risks into your uncertainty budget and schedule more frequent verification where site conditions are harsh.

Calibration: Methods That Deliver Trust

Calibration proves the meter reading against a defined reference and records the measurement uncertainty.

Choose a calibration method that matches the meter technology and the commercial risk attached to the measurement.

Gravimetric and Prover Methods Explained

Gravimetric calibration is the highest-accuracy option for small to medium flows because it measures mass directly by weighing the collected product.

For larger pipelines, pipe provers, sphere provers and master meters are used for field verification and custody transfer, each with documented uncertainty.

Transfer Standards and Laboratory Calibration

When a site cannot host a primary standard, use transfer standards or accredited mobile provers, but keep the traceability chain short and fully documented.

Use ISO 17025 accredited laboratories or providers and keep calibration certificates with the meter record so results are defensible in commercial and regulatory settings.

Calibration Schedule

Set calibration intervals by considering meter stability, how the site operates and the commercial risk of the measurement.

High-value billing points and harsh sites usually need more frequent checks than meters used for process control.

Practical Verification Schedule

Begin with the manufacturer recommended interval and shorten it if you see drift, excessive wear or challenging site conditions.

Use inline verification checks and portable tools between full calibrations to catch issues early and avoid surprises at billing time.

Compliance and Accreditation

Using accredited labs and aligning with international standards builds trust with customers and regulators.

Maintain calibration traceability to national standards and use ISO 17025 accredited providers where possible.

Which Standards to Reference

List the exact standards that apply to your product and industry, noting relevant clauses or test methods where useful.

Provide a short note on why each standard matters for billing accuracy so contracts are clear and disputes are easier to resolve.

Practical Steps to Improve Existing Metering Systems

Start by auditing high-value meters and completing a full site verification, then fix the few components that cause most uncertainty rather than replacing entire systems.

Quick wins:

- Check straight runs and pipe condition.

- Confirm meter zero and linearity.

- Inspect for leaks and electrical noise.

- Verify grounding and signal cabling.

- Document findings and prioritise corrective work.

Short Technical Checklist Before You Buy

Before you buy, confirm the following:

- Fluid compatibility and that wetted materials suit your product.

- Required accuracy and the expected flow range under site conditions.

- Availability of the recommended straight runs and any need for flow conditioners.

- Calibration options and whether calibration is traceable to national standards.

- A documented uncertainty budget and recent ISO 17025 calibration certificates for the proposed meter.

For a practical comparison of electromagnetic and ultrasonic meters, see the electromagnetic vs ultrasonic guide.

Secondary Metering

A second meter or periodic cross-check reduces commercial risk and establishes confidence in the primary reading. Redundancy supports rapid dispute resolution and provides a fall back during maintenance.

How to Use a Check Meter Effectively

Install the check meter with an independent data logger and compare logs over a defined window. Investigate differences rather than ignoring small mismatches.

Calibration SOP

A written SOP turns calibration into a predictable business activity rather than an ad hoc job. Include pre-commissioning checks, calibration steps, acceptance criteria and record handling.

For practical routines on preventing downtime through regular calibration and maintenance, see the calibration and maintenance guide.

Training and Competence

Only use trained personnel or accredited providers for billing-grade verification. Keep training records and tie competence to the SOP for quality assurance.

Why Choose Minerva

We pair trusted metering hardware with hands-on engineering support and optional remote monitoring, so you get accurate readings and ongoing confidence.

We supply meters, manage site installation, perform ISO-traceable calibration and run ongoing diagnostics to keep commercial meters working as intended.

For more on Minerva’s flow metering capabilities see the Minerva flow metering page.

Make Billing Errors a Thing of the Past

Want to stop revenue leakage now? Protect your bottom line and remove billing doubts with measurement you can trust.

Book a calibration assessment or technical consultation with us today.