TL;DR: Integrating gas detection with plant safety turns hidden gas risks into clear, automatic actions. Link fixed, portable and personal detectors to PLC, BMS, DCS or SCADA so alarms start ventilation, shut equipment or trigger evacuation within seconds.

Key Takeaways:

- Map hazards where gas can collect and where people actually work.

- Match sensor type and range to each gas and environment, and set points for the lowest credible leak.

- Keep alarm messages short and tied to specific actions, then train and drill.

- Prove performance with end to end tests, logs and a predictive maintenance plan.

Gas is invisible, fast moving, and unforgiving. Many plants still rely on procedures, training, and PPE as their first lines of defence.

All three matter, but none of them can tell you that methane is building under a mezzanine or that oxygen levels dropped two minutes ago in a sump.

That’s what an integrated gas detection system is for – to turn hidden hazards into clear signals your team can act on.

The Blind Spot That Isn’t Written Into Your SOPs

Standard operating procedures cover isolation, permits, lockout and alarms, but they often miss how gas hazards change second by second.

A checklist can’t keep pace with a dynamic leak, a purge gone wrong or maintenance that stirs up residue.

When Procedures Aren’t Enough

- Confined space entry: A pre-entry check clears the pit. Ten minutes later, welding heat displaces oxygen and your spotter doesn’t see it coming.

- Start-up and commissioning: Flammable gas pockets sit in dead-legs. Vent lines stir them loose just as operators are walking the line.

- Turnarounds: Contractors bring battery tools and solvents; temporary ventilation struggles; detectors in the wrong place stay quiet.

Integrated detection closes this gap by watching continuously and acting automatically when thresholds are crossed.

If integrating gas detection plant safety is your goal, the steps below show how to connect detection to real actions.

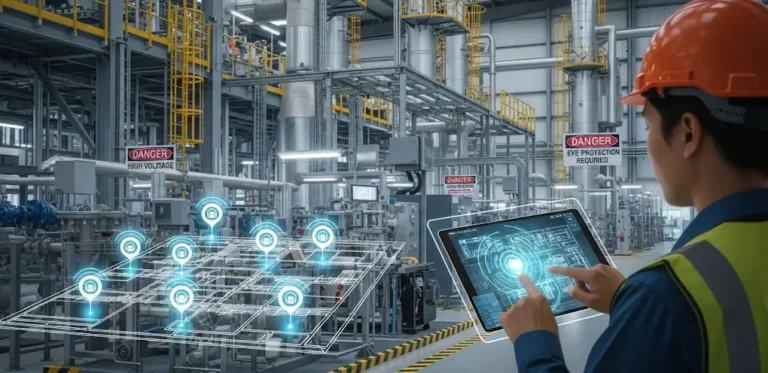

What “Integration” Actually Means (And Why It’s Not Just Wiring)

Integration isn’t just adding a few sensors. It means linking your fixed gas detectors, local displays/controllers and personal or portable detectors to the plant PLC, BMS, DCS or SCADA.

So alarms trigger the right action, start ventilation, shut down equipment, evacuate or send a quick radio call with no guesswork.

Signals That Matter

- Combustible gases: Alarm at a safe percentage of LEL; interlock fans and ignition controls before the mix gets dangerous.

- Toxic gases: Use TWA and STEL logic so both acute spikes and slower build-ups count.

- Oxygen: Low-O2 alarms protect confined spaces; high-O2 alarms catch enrichment risks.

The Integration Blueprint You Can Copy Today

You don’t need a mega-project to get this right. Follow a simple blueprint and scale it.

1. Map Hazards, Not Just Floor Plans

Walk the plant with operations and maintenance, following the paths people actually take and the spots where they stop.

In each area, list the gases by process step, cleaning chemical and by-product, and record how air moves, where it vents, and where crews normally stand.

2. Define Detection Roles by Zone

- Fixed detectors for continuous monitoring in process and storage zones.

- Transportable units for temporary work fronts during shutdowns.

- Personal wearables for entries and walk-arounds.

3. Pick the Sensing Tech per Hazard

Match the sensor type, range and known interferents to each gas and environment, not just what is on the shelf.

Design for the lowest credible leak you need to catch early, and set ranges and calibration routines to spot it before it becomes a worst case.

If you handle specialty gases in fabs, this short guide on advanced techniques for toxic gas detection in the semiconductor industry shows where extra coverage pays off.

4. Agree the Cause-and-Effect

Build a clear cause and effect matrix that ties every alarm setpoint to a specific action such as ramping fans, tripping package skids, locking access doors, sending a radio message and notifying the control room.

State who can reset the alarm and when to escalate to site evacuation so nobody has to guess under pressure.

5. Wire it into Permits and Isolation

Embed bump test checks and live detector status into your permit to work screens so supervisors see risk at a glance.

If the nearest fixed detector is inhibited or bagged, the system should block permits in that zone until protection is restored.

6. Alarm Rationalisation the Right Way

Cut alarm clutter by using Tier 1/2/3 priorities, distinct tones and strobes, and short plain language messages like “Bay 4 H2S 5 ppm – Vent ON.”

Keep the list small, make each alarm meaningful, and write messages so operators never have to decode jargon.

7) Test it Like You Mean It

Run functional tests end to end using smoke, test gas or simulator signals at the head to confirm the local display, the upstream signal and the physical action such as fans, trips or messages.

Document results, failures and fixes so you can prove performance to auditors and improve the design.

8) Close the Loop with Training

Teach people what each alarm sounds like, what it means, and the first three actions they must take, then practise with short drills.

Refresh training after any design change, nuisance event or incident, and keep quick reference cards at the panel.

Cost Myths That Slow Good Projects

Myth 1: We’ll drown in false alarms.

That’s a design and rationalisation problem, not a detection problem. Vote where needed, tune setpoints, and standardise messages.

Myth 2: Integration will disrupt production.

Staged rollouts by zone, with off-line testing against simulators, keep risk low while you upgrade.

Myth 3: It’s cheaper to add more PPE.

PPE protects people after exposure. Detection prevents exposure by changing the environment and the behaviour before harm.

Myth 4: We can’t retrofit old panels.

You can translate signals with local controllers and gateways, then push clean data to legacy PLCs or SCADA. Start at your highest-risk area and expand.

Implementation Pitfalls To Avoid

- Copy-paste designs: Lifting a design from another site without checking gas behaviour, airflow and work patterns on your floor is risky. Validate with a short survey and a simple smoke or test-gas check before you sign off.

- Unlabelled beacons and horns: When strobes and sirens aren’t labelled, people pause instead of moving. Add clear labels and a one-line action so crews know what to do and where to go.

- No maintenance plan: Without a plan and spare sensors, one failed head can leave a quiet blind spot. Build bump tests and calibrations into the CMMS and keep spare heads on the shelf.

- Ignoring temporary states: Bypasses, inhibited points or heads bagged during painting are easy to forget. Set a visible temporary-risk alert with an expiry so protection is restored as soon as the job is done.

For a smarter program, see this quick guide to implementing predictive maintenance for gas detectors.

Why Choose Minerva

Gas detection should work with your safety protocols, not sit beside them.

Minerva unifies fixed, portable and personal detection with central controllers, streaming clean signals to PLC, BMS, DCS or SCADA to trigger ventilation, shutdown or evacuation fast.

With over three decades serving Malaysian industry, Our Team covers hazard mapping through installation, commissioning, calibration and service.

We build custom setups, integrate with legacy panels and CMMS, and write clear operator docs.

Book A Safety Integration Consult

Ready to connect your gas detection with the rest of your safety system?

Tap a consultation now and you will leave with a phased action plan, budget guidance and clear next steps for design, commissioning and maintenance.