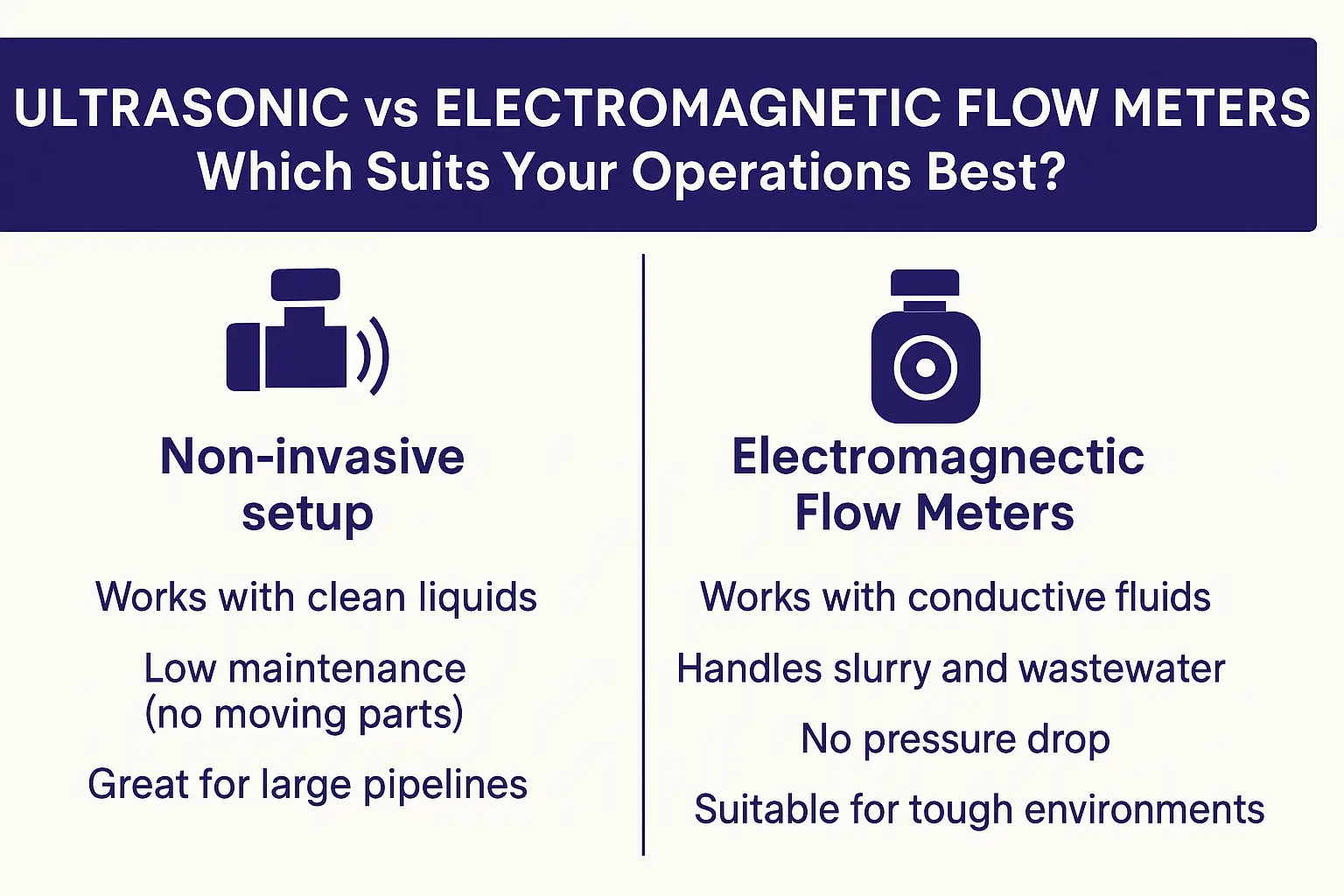

TL; DR: Ultrasonic and electromagnetic flow meters each have strengths and limits. Ultrasonic models are easier to install and work well with clean fluids, while electromagnetic meters are more accurate and handle dirty, conductive liquids. Choosing the right one depends on your fluid type, accuracy needs, and installation conditions.

Key Takeaways:

- Ultrasonic meters are ideal for clean water and retrofits without cutting pipes.

- Electromagnetic meters provide higher accuracy and suit conductive or contaminated fluids.

- Installation and long-term maintenance requirements vary significantly between the two.

- Always match the meter type to your fluid properties, budget, and accuracy expectations.

Flow meters might seem straightforward devices at first glance, but they’re actually the hidden champions behind smooth operations and smart resource management. Choosing between ultrasonic and electromagnetic options can be the difference between smooth processes and costly setbacks. Before you make that choice, it’s important to understand exactly how each type works, what makes them different, and why it matters for your operation. You’ll soon see how each option can fit different situations without overcomplicating your decision.

Why Your Choice of Flow Meter Matters More Than You Think

Flow meters are essential tools that directly impact measurement accuracy, process reliability, and cost control across water and industrial applications. They measure how much fluid moves through a pipe, verify that systems operate as intended, and support consistent output. The right meter can boost efficiency and cut costs, while the wrong one leads to errors and expensive downtime.

Common Mistakes in Flow Meter Selection

Here are some of the issues that come up most often when teams pick a flow meter:

- Rushing the decision without considering fluid type, installation needs, process temperature, or specific accuracy requirements

- Picking a meter incompatible with highly conductive liquids

- Choosing a model that’s hard to maintain, which can lead to repeated failures and unexpected expenses

For a more detailed guide in selecting flow meters, read: Guide to Selecting Flow Meters

Ultrasonic Flow Meters: Silent Precision in Action

Ultrasonic flow meters measure liquid volume using sound waves. They are common for clean water and low-viscosity fluids. Because they use acoustic signals instead of mechanical parts, they avoid leaks and contamination risks. They’re also ideal for retrofits or when shutdowns aren’t possible.

How Ultrasonic Technology Measures Flow

Ultrasonic flow meters measure flow by sending signals diagonally across the pipe. A transducer emits a pulse that moves downstream faster than upstream, and the processor compares the travel times to determine velocity and calculate volume. In clean water pipelines, sensors are mounted on opposite pipe walls to capture these signals clearly and provide reliable readings.

Benefits of Ultrasonic Meters

Ultrasonic meters offer several strengths that set them apart from other technologies. Here are some of the main advantages to consider:

- Easy clamp-on installation without cutting pipes or stopping flow.

- No moving parts, reducing wear, keeping accuracy consistent, and allowing use on many pipe sizes.

- Lightweight design for easy handling and minimal maintenance even in tight spaces.

When Ultrasonic Meters Might Not Be Ideal

While they have clear benefits, ultrasonic meters also come with limitations worth understanding:

- Highly aerated or mixed fluids can affect accuracy or cause erratic readings.

- Low flow rates are harder to measure accurately.

- Vibration or temperature swings can disrupt the ultrasonic signal and reduce measurement stability.

Electromagnetic Flow Meters: The Workhorse of Liquid Measurement

Electromagnetic flow meters measure conductive liquids by applying electromagnetic principles: moving fluid through a magnetic field generates a voltage signal. This signal is used to calculate the flow rate accurately. Because there are no moving parts in contact with the liquid, these meters stay reliable over time and can handle dirty, abrasive, or corrosive fluids without significant wear.

How Electromagnetic Flow Meters Operate

Electrodes are mounted inside the meter body, aligned perpendicular to the fluid flow. As the conductive liquid passes through the magnetic field generated by coils around the pipe, it induces a voltage across the electrodes. This voltage is directly proportional to the flow velocity and is processed by the transmitter to calculate precise flow rate readings.

Advantages of Electromagnetic Meters

Electromagnetic meters offer several advantages that make them popular across industries. Here are some of the reasons they stand out:

- High accuracy (±0.5%), suitable for billing and compliance.

- No pressure loss and reliable measurement of dirty fluids like slurries and wastewater.

- Long life with corrosion-resistant linings and sizes for small lines to large municipal pipelines.

Limitations of Electromagnetic Meters

- Can’t measure non-conductive liquids like oils.

- Sensitive to air bubbles or empty pipes, which can cause false readings and reduce accuracy. They may also need cleaning if buildup forms on electrodes, especially in wastewater applications.

- Require proper grounding to avoid interference and have higher installation costs because the pipe needs modification.

Ultrasonic vs Electromagnetic: A No-Nonsense Comparison

Accuracy and Reliability

Electromagnetic meters typically achieve higher accuracy, often within ±0.5%, and maintain stable readings even when fluid properties vary. They are well suited to applications requiring precise billing or regulatory compliance. Ultrasonic meters can still be precise but usually fall within ±1–2% accuracy, which is acceptable for general monitoring.

Installation and Maintenance

- Ultrasonic meters clamp onto pipes without cutting or stopping flow, making installation simpler and faster.

- Electromagnetic meters require the pipe to be opened for insertion and properly grounded to avoid interference, but once installed, they need less frequent recalibration.

Cost Considerations

Ultrasonic meters generally have lower upfront costs and installation expenses. Over time, they can incur more maintenance if process conditions are challenging. Electromagnetic meters cost more initially but often have lower lifecycle costs due to durability.

Compatibility with Liquids

- Electromagnetic meters can measure any conductive liquid, including wastewater, sludge, and slurries.

- Ultrasonic meters work best with clean or lightly contaminated fluids and may struggle with air bubbles, heavy solids, or low flow conditions.

| Feature | Ultrasonic Meters | Electromagnetic Meters |

| Accuracy | ±1–2% | ±0.5% |

| Installation | Clamp-on | Inline |

| Maintenance | Occasional recalibration | Less frequent recalibration |

| Upfront Cost | Lower | Higher |

| Lifetime Cost | Can be higher | Generally lower |

| Compatibility | Clean liquids | Any conductive liquid |

Key Questions to Ask

What type of liquid will you measure?

- If it’s clean water, ultrasonic meters may work best. For slurry or wastewater, electromagnetic meters are usually better.

Is conductivity an issue?

- Non-conductive fluids rule out electromagnetic meters.

What level of accuracy do you need?

- For billing or compliance, electromagnetic’s ±0.5% is often required.

Are there space or installation constraints?

- Clamp-on ultrasonic meters avoid cutting pipes and fit tight spaces.

Why Choose Minerva Intra?

At Minerva Intra, we help you make an informed decision. Our team has decades of experience specifying and installing flow meters for water utilities, industrial plants, and commercial facilities. We understand that every project has unique requirements, budgets, and timelines. We offer hands-on support during planning, installation, and maintenance. We can help you evaluate your process, select the right model, and set up a meter that will stay accurate for years to come.

Ready to Find the Perfect Fit?

If you’re considering upgrading or replacing your flow meters, we’re here to help. Our team can walk you through options, recommend models that fit your budget and technical needs, and handle installation from start to finish.

Explore our range of ultrasonic and electromagnetic flow meters or contact us today to get expert advice tailored to your project. Your operations deserve nothing less than precise, dependable measurement. You can also learn more about our broader engineering services, including calibration, installation, and maintenance support, on our Engineering Services page.